COMOS at a glance

Description

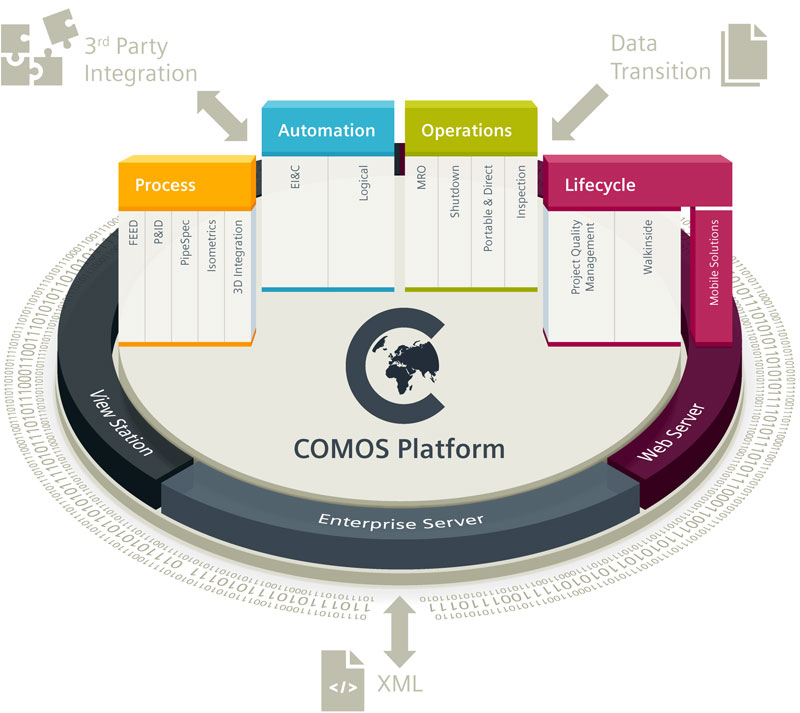

With its unified data platform the integrated software solution COMOS provides plant design engineers, plant operating personnel, company management, and solution partners with a continuous flow of data that meet their specific needs across all project phases.

One requirement for effective plant management is optimum networking and coordination of all disciplines and departments involved in the engineering and operation of a plant. The software solution COMOS is the basis for the cooperation of worldwide collaboration across the entire lifecycle of a plant.

The integrated COMOS software concept is based on object orientation. Components are described holistically and displayed graphically in their true-to-life representation. The graphical and data-related description, which includes all data associated with the component, forms a single unit within the database – the object. Related data sheets, lists, and other documents are linked to the corresponding objects.

The complete plant information is stored in a central database. As a result, COMOS allows all disciplines and departments involved in the engineering and operating phases to always access the same data for a given object. Objects can be processed in COMOS bidirectional on data sheets as well as in technical drawings. This means that changes to objects or documents are always available to every user worldwide, whatever the time zone, and that they are up-to-date and consistent. The entire plant, right down to the individual components, can be examined and further developed from a functional and interdisciplinary perspective.

The open system architecture of COMOS can be adapted to exactly meet company-specific requirements, allows links to third-party systems and can be integrated into existing EDP (Electronic Data Processing) landscapes.

Security information

To ensure the secure operation of a plant or machine it is also necessary to take suitable preventive action (e.g. cell protection concept) and to integrate the automation and drive components into a state-of-the-art holistic industrial security concept for the entire plant or machine. Any third-party products that may be in use must also be taken into account.