COMOS EI&C

Optimized Electrical, Instrumentation & Control system engineering with COMOS EI&C.

Description

COMOS EI&C represents a software solution which details and specifies all functional EI&C data that was schematically described during process planning. This is optimized by the seamless connection to upstream process engineering.

Switchboard systems including automation solutions can be planned easily and thus be discribed in a single-lined (simplified circuit diagram representation) or multi-lined (detailed representation) standard-based representations.

The interlinking with fluid technology allows for data from the EI&C engineering or previous planning steps to be available to the fluidics engineer for easy further processing as well.

Benefits

- Increased engineering quality through consistently objectoriented EI&C engineering

- High transparency through seamless transition from basic to detailed engineering

- Time and cost savings through minimization of iteration loops

- Reduced costs through early estimation of required devices and materials

- Incorporation of external partnersor suppliers without dataor quality lossSignal tracking

- Discipline-specific fluidics implementation

- Accelerated fluidics engineering through unique logic functions and automatisms

Design and function

Standardized object libraries are available to the user for the generation of circuit and connection diagrams, etc. The objects can be immediately used and individually adjusted or newly created.

The COMOS Marshalling Designer supports bulk creation of signal routes in organizational charts. Flexible cable, terminal and I/O assignments are supported. Autoloops are created on the basis of routing data: Connections do not need to be drawn in cable-by-cable, but are generated automatically. The resulting documents such as terminal diagrams, cable lists, parts and order lists are generated by the software automatically and revisions are documented reliably.

Fluidic diagrams can be configured by selecting the components from drop-down lists and simply positioning the components on the circuit diagram by means of drag & drop. The creation of parts lists, piping lists, tubing lists and lubrication point lists is carried out automatically.

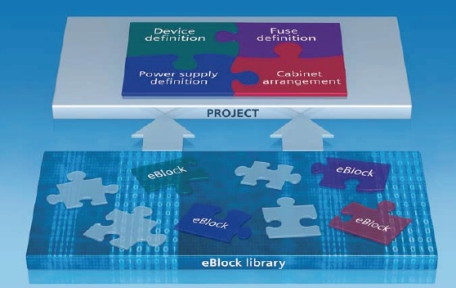

The eBlock technology (= engineering block technology) represents a COMOS solution for the intelligent management of assemblies for step-by-step engineering with progress control and workflow support. The tasks defined in the eBlocks and the dependencies between the engineering disciplines are displayed as plain text instructions and reliably guide the engineer through the decision process.

As an open system, COMOS offers numerous interfaces to other systems. For example, COMOS EI&C features interfaces to all conventional automation systems such as SIMATIC.

Security information

To ensure the secure operation of a plant or machine it is also necessary to take suitable preventive action (e.g. cell protection concept) and to integrate the automation and drive components into a state-of-the-art holistic industrial security concept for the entire plant or machine. Any third-party products that may be in use must also be taken into account.